Lab Notes: IGI 1239 Paraffin Wax

To help you get the best results out of IGI's 1239 A paraffin wax, we're sharing our lab notes. Read below to see our results. And as always, please contact us with questions. We're happy to help!

Our testing process

We divided our testing into three parts:

- Aesthetics: We tested for shrinkage, mottling, and color retention.

- Fragrance Performance: We looked at solubility, retention, and cold and hot throw performance.

- Burn Performance: We tested various LX wick sizes to find the best burn.

We used our Lush Linen and Grapefruit and Mint fragrance oils for the fragrance testing. They have very different densities, viscosities, and ingredients. We hoped the variation would reveal potential solubility and burn issues.

General overview

Application: Pillars, Votives, Tarts, and Cut and Carve

Recommended Fragrance Load: 3%

The wax comes in approximately 10 lb (4.5 kg) slabs and is quite hard. Raw slabs do have a translucent look and the characteristic paraffin odor. The higher melt point of this wax does require more time to meltdown and bring up to temperature. In our testing, we found 3 lbs (1.4 kg) took 60 minutes to bring to 190ºF (87.8°C). The characteristic odor intensified as the wax melted and came up to temperature. But we didn’t detect the smell in our finished candles.

This wax is an alternative to the IGI 1343 A that was discontinued by the manufacturer in early 2018. We found this wax was more likely to mottle than IGI 1343.

Aesthetics

For pillars

We tested this wax in pillar candle molds with wick pins. We poured test candles at temperatures ranging between 175°F and 185°F (79.4°C and 85°C), and let them sit overnight. After 24 hours, the candles had significant shrinkage around the wick pin. They required a second pour to get a level bottom.

We did not use mold release and the wax came out of the molds very easily. Their finish was quite smooth with some mottling present.

For votives, clamshells, and tarts

We poured our votives and clamshells at 175°F (79.4°C). After 24 hours, the wax had significant shrinkage. They required a second pour to get a level surface. The tart mold and clamshell did have shrinkage through the center, but the edges did not shrink. This made it difficult to top off which caused an uneven finish to the surface. We recommend to not fill these molds all the way so that a second pour can achieve a more level surface.

We did not use mold release, and the votive candle and wick pins came out easily. The clamshells also un-molded easily. Because the wax is quite hard, we had some trouble breaking the cubes apart. The tart molds were a little resistant to un-molding. A mold release would be useful.

Dipping bears and cut and carve

While we don’t specialize in these methods, we found the wax quite malleable while warm and could easily carve it with a knife. We believe you’ll find this is an easy wax to work with in either of these applications.

Mottling

We noticed inconsistent mottling in all applications based on the wax’s temperature. To achieve a smooth surface, we recommend insulating the mold to keep it warm. For better mottling results, keep the mold as cool as possible.

Because we couldn’t control temperature, our second pour produced significantly more mottling on the bottom of our pillars and tops of our votives and melts.

Coloring

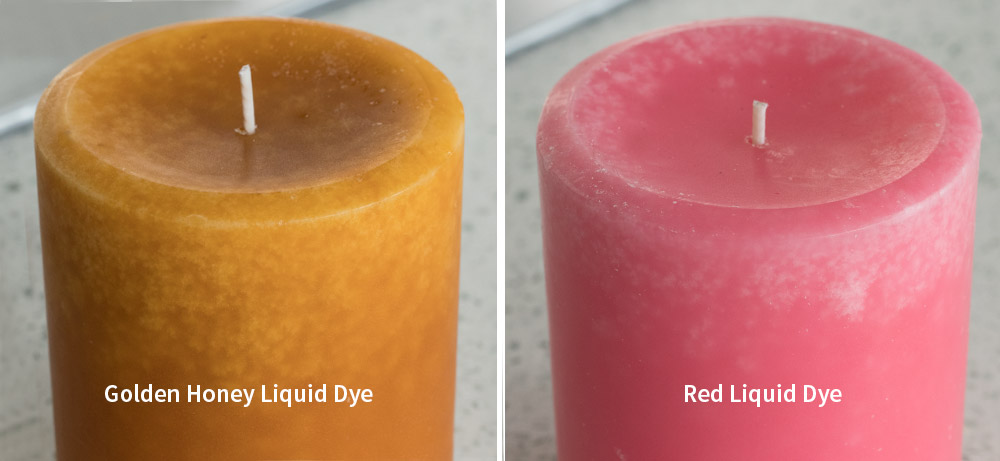

We tested two colors of liquid dye: red and golden honey. We used one drop of golden honey in 1 lb (454 g) of the wax and it produced a nice golden tan shade. We used one drop of red in 2 lbs (907 g) of wax and it produced a vibrant reddish pink shade. The dye mixed quickly and easily at various temperatures from 170 - 190ºF (76.7-87.8°C).

Fragrance performance

Solubility

We added fragrance to the melted wax at 190ºF (87.8°C). The fragrance incorporated easily, and we didn’t see signs of separation. We found that a usage rate of 3% (0.5 oz per pound of wax or 14 g per 454 g) or less required no additives. However, after we initially unmolded, the candles and tarts were oily to the touch. After 48 hours, the fragrance absorbed into the wax and did not reappear.

Hot and cold throw

The cold throw of the candles was quite strong. We thought this may be attributed to the oil that seeped to the surface more than the scented wax itself. After two weeks, the cold throw was still very strong.

After 48 hours we began our burn and melt tests. The votive filled a small room in 30 minutes and was very strong (solid 3 out of 3 on our scale), and the wax melts were equally strong.

Despite the seemingly low fragrance load, the cold and hot throw was great.

Burn performance

Wicking

We tested the wax with our LX series for pillars and votives. Both burned well with the LX series. We found the wicking to be similar to what we previously recommended for 1343 in our wick guide.

As always, we strongly recommend that you test this wax with your fragrances and dyes for best results. And remember, we’re always here to help with questions. Text 919-891-6226, email support@candlescience.com, or connect with us on Facebook, Twitter, or Instagram.