How are fragrance oils made? A look into the process of bringing a fragrance oil to life, from initial concept to final product.

For many makers, fragrances are a huge part of their love for crafting scented products. Fragrances offer a sensory experience that can transcend the mundane, evoking memories, emotions, and atmospheres in just a whiff. They have the ability to transport us to different times and places, and infuse our surroundings with a touch of magic and personality.

But have you ever wondered what exactly goes into creating the fragrance oils that you enjoy so much? As fellow fragrance lovers, we thought you’d like to know more about the fascinating journey of how CandleScience fragrance oils are made.

What fragrance oils are and what they're used for

Fragrance oils are concentrated liquid aromas made from natural ingredients like essential oils and synthetic compounds. They differ from pure essential oils because, though many contain natural materials, they are predominantly comprised of synthetic chemicals. The benefits of synthetic fragrance oils include their consistency in scent profile, stability and long-lasting aroma, and performance.

Formulated to be mixed into a base, fragrance oils are used in a variety of applications. Most of us are familiar with them in candles and wax melts, reed diffusers, soaps, and leave-on body products like lotion. However, fragrance oils are also used in perfumes and fine fragrances, detergents, toiletries, cleansers, and other household products, to name just a few other common uses.

How fragrance oils are made

Producing and bringing fragrance oils to market requires many experienced professionals. In the case of CandleScience fragrances, the two main players are fragrance houses and our own team.

Fragrance houses are companies that design and manufacture fragrances. Fragrance houses employ expert perfumers, perfumer assistants, and evaluators who are key in creating the scents. Teams of marketing, quality assurance, and manufacturing specialists usher the fragrances to completion.

As the supplier that sells the finished fragrance oils to the maker community, our in-house product development team takes the lead and works closely with fragrance houses to design and create fragrance oils. Our operations, fulfillment, quality control, marketing, and customer support teams are then integral to bringing the fragrances to you.

Working together, we and our fragrance house partners go through a five-step process to create and ultimately sell fragrance oils:

1. Conceptualization

2. Formulation and evaluation

3. Testing and approval

4. Manufacturing

5. Distribution

Fragrance oil conceptualization

When the CandleScience product development team develops our original fragrances, conceptualization comes first—and it’s a fun and creative part of the process! Ideas for new fragrance oils can come from our team, a fragrance house, or through a collaboration between the two.

Fragrance ideas are often generated by the product development team who identifies gaps in the overall fragrance collection. A perfect example of this is our Olive Leaf and Citron fragrance oil. Until its release, we did not carry a fragrance with an olive note in it. Customer requests can also lead to the creation of new scents. Our Petrichor fragrance oil came to be because so many of you expressed a desire for this unique wet, earthy scent. No matter the origin of a fragrance idea, we then submit a creative brief to one or more fragrance houses. The brief contains information about the fragrance’s concept and includes parameters about its intended use, CleanScents formulation standards, and desired price point.

Because fragrances are the specialty of fragrance houses, they naturally stay on top of consumer preferences. So it’s common for them to propose fragrance concepts identified through market research or influenced by color, fine fragrance, fashion, lifestyle, and flavor trends. Our Yuzu Blossom fragrance oil was inspired by the fruit’s culinary popularity and was a scent concept originally presented to us by a fragrance house. We ultimately added this bright fragrance to the CandleScience lineup because it connected with a trend and filled a whitespace for yuzu in our fragrance library.

In the landscape of candle and soap making suppliers, you’ll find a range of approaches to fragrance creation and curation. Working directly with an established fragrance house to design and produce original fragrance oils is just one way—and is our method.

However, some suppliers purchase pre-made fragrance oils, and then rename and repackage them for sale. In other cases, suppliers source oils from domestic fragrance manufacturers that specialize in recreating popular home fragrances, fine fragrances, and personal care brands called duplications or “dupes.”

Fragrance oil formulation and evaluation

Once a fragrance concept is devised, the fragrance house’s team of perfumers and perfumer assistants set out to formulate it.

Taking safety guidelines, planned application, and budget into consideration, perfumers use their extensive knowledge of raw materials and chemistry to compose the fragrance. They work with thousands of fragrance ingredients ranging from natural oils, essences, and other natural materials, to lab-created aromatic compounds and synthetic chemicals.

These main components of the fragrance come in varying forms from liquid to solid. Perfumer assistants work closely with the perfumers to compound the materials, adapt their forms as needed with solvents and diluents, and precisely measure the ingredients.

After the initial formulation is complete, the fragrance is then put into the intended base. The evaluator and perfumer assess the fragrance’s scent profile and work together to refine it as needed.

Fragrance testing and approval

When the character of a fragrance formulation is deemed satisfactory, the fragrance house team conducts numerous tests that analyze the fragrance’s performance and stability in the intended applications. In the case of candle fragrance oils, this includes rating the fragrance’s cold throw in wax, and its hot throw when in lit candle form.

Once a fragrance oil meets all of the fragrance house’s standards, a sample is sent to us for review. Our product development team conducts their own series of tests and may request that the fragrance house adjust the fragrance to better meet their needs. Case in point: Forest Chai fragrance oil went through four rounds of modifications to perfect its complex, spicy-woody scent and improve the hot throw.

In some instances, fragrance formulas do not make it through this phase. Common reasons include additional tests that reveal unsatisfactory performance, or because—as new fragrance safety data emerges—a component ingredient in the fragrance no longer meets our Clean Scents standards. However, once a fragrance oil is approved after in-house tests and evaluations are completed, then it’s on to the next step: manufacturing.

Manufacturing

Upon approving a fragrance oil, we submit a purchase order to the fragrance house. The fragrance house generates a bill of manufacturing and the manufacturing step of the process begins!

The fragrance house manufactures fragrance oils in state-of-the-art environments using sophisticated equipment and automated processes to ensure consistency and precision. Raw materials, housed in smaller tanks, are dispensed into large-capacity mixing tanks where the ingredients are thoroughly blended to create the final fragrance oil.

Then, the fragrance house quality tests samples of the finished fragrance oil before packaging them into metal drums and shipping them to us.

Distribution

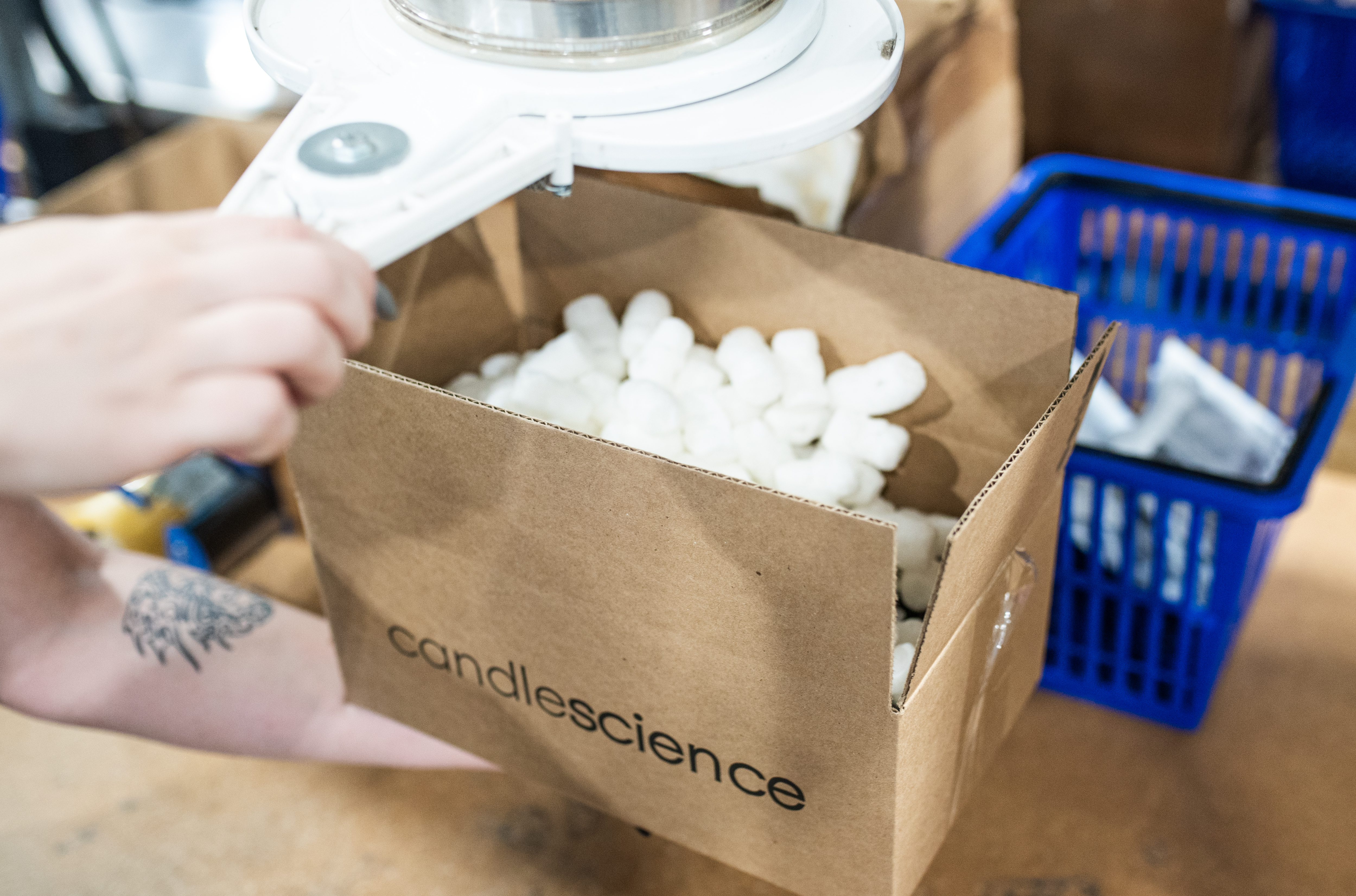

When the fragrance drums arrive at our warehouse, they’re inspected and checked once more by our quality control team. Samples are poured for the marketing, support, and showroom teams for blending and project ideas. The fragrance is then prepared for pouring into bottles and containers.

At CandleScience, we pour fragrance oils into containers by weight (rather than volume) using proprietary, custom-built machinery. The machines precisely pour the fragrances to ensure customers receive the correct amount every time.

As orders arrive, our fulfillment team does a final test twist of the cap, checks that the fragrances are safely packed for transport, and out the warehouse door they go! Our trusted shipping partners then deliver your order to your home or business, whether it’s a few 1 oz bottles of fragrance oils or a full pallet of supplies.

Final thoughts on fragrance oils

Behind every fragrance oil is a story that combines creativity, science, and craftsmanship. From concept to realization, each step of crafting a fragrance oil involves years of dedication and expertise. So the next time you reach for a bottle of your favorite fragrance oil, we hope this article helps you appreciate the blend of art and chemistry that went into its creation.